The increasing prevalence of industrial accidents captured on video has sparked global concern, particularly when it comes to machinery operations such as lathes. The term "Russian lathe accident video" has become a trending search phrase, drawing attention to the importance of workplace safety and the dangers associated with heavy machinery. In this article, we will delve into the significance of these videos, their impact on safety awareness, and the lessons we can learn from them.

Industrial accidents have long been a topic of concern in the manufacturing sector. The rise of online platforms has made it easier for people to share videos of such incidents, including those involving lathes. These videos often serve as cautionary tales, highlighting the potential risks and emphasizing the importance of proper training and adherence to safety protocols.

While the term "Russian lathe accident video" may evoke curiosity, it is crucial to approach this subject with sensitivity and a focus on prevention. By understanding the causes and consequences of these accidents, we can work towards creating safer working environments and reducing the likelihood of similar incidents occurring in the future.

Read also:Elon Musks Second Wife A Deep Dive Into His Life And Relationships

Table of Contents

- Introduction to Lathe Accidents

- Understanding Russian Lathe Accidents

- Common Causes of Lathe Accidents

- Impact of Videos on Safety Awareness

- Preventing Lathe Accidents

- Safety Training and Procedures

- Case Studies of Lathe Accidents

- Importance of Machinery Maintenance

- Legal and Regulatory Considerations

- Conclusion and Future Perspectives

Introduction to Lathe Accidents

Lathe machines are essential tools in the manufacturing industry, used for shaping metal, wood, and other materials. However, their operation involves significant risks if proper safety measures are not followed. The "Russian lathe accident video" phenomenon has brought attention to the dangers associated with these machines, particularly in countries where safety standards may not be as stringent.

Types of Lathe Machines

There are various types of lathes, each designed for specific purposes. Some common types include:

- Engine lathe

- Toolroom lathe

- CNC lathe

- Wood lathe

Understanding the differences between these machines is crucial for ensuring safe operation.

Understanding Russian Lathe Accidents

Accidents involving lathes in Russia have been documented in numerous videos, highlighting the need for improved safety practices. These incidents often occur due to a combination of factors, including lack of training, outdated equipment, and inadequate supervision.

Factors Contributing to Russian Lathe Accidents

Several key factors contribute to the prevalence of lathe accidents in Russia:

- Poor maintenance of machinery

- Inadequate safety training for operators

- Failure to adhere to safety protocols

Addressing these issues is essential for reducing the incidence of accidents.

Read also:What Is Reggie Youngblood Net Worth Discover The Wealth Of The Rising Star

Common Causes of Lathe Accidents

Lathe accidents can result from a variety of causes, many of which are preventable. Some of the most common causes include:

- Improper use of personal protective equipment (PPE)

- Operator error due to lack of experience or training

- Mechanical failures or malfunctions

By identifying these causes, we can implement strategies to mitigate the risks associated with lathe operation.

Impact of Videos on Safety Awareness

The proliferation of "Russian lathe accident video" content has had a significant impact on safety awareness worldwide. These videos serve as powerful reminders of the potential dangers of working with heavy machinery and the importance of adhering to safety guidelines.

Benefits of Video Documentation

Documenting accidents through video can provide valuable insights into the causes and consequences of such incidents. Some benefits include:

- Increased awareness of safety hazards

- Improved training materials for operators

- Enhanced understanding of risk management strategies

However, it is important to approach these videos with sensitivity and a focus on learning rather than sensationalism.

Preventing Lathe Accidents

Preventing lathe accidents requires a multi-faceted approach that addresses both human and mechanical factors. Key strategies include:

- Providing comprehensive safety training for all operators

- Regularly maintaining and inspecting machinery

- Implementing strict safety protocols and enforcing compliance

By prioritizing prevention, we can significantly reduce the incidence of lathe-related accidents.

Safety Training and Procedures

Effective safety training is critical for ensuring that lathe operators are equipped with the knowledge and skills necessary to perform their jobs safely. Training programs should cover:

- Proper use of PPE

- Machine operation procedures

- Emergency response protocols

In addition, regular refresher courses and safety drills can help reinforce these important concepts.

Case Studies of Lathe Accidents

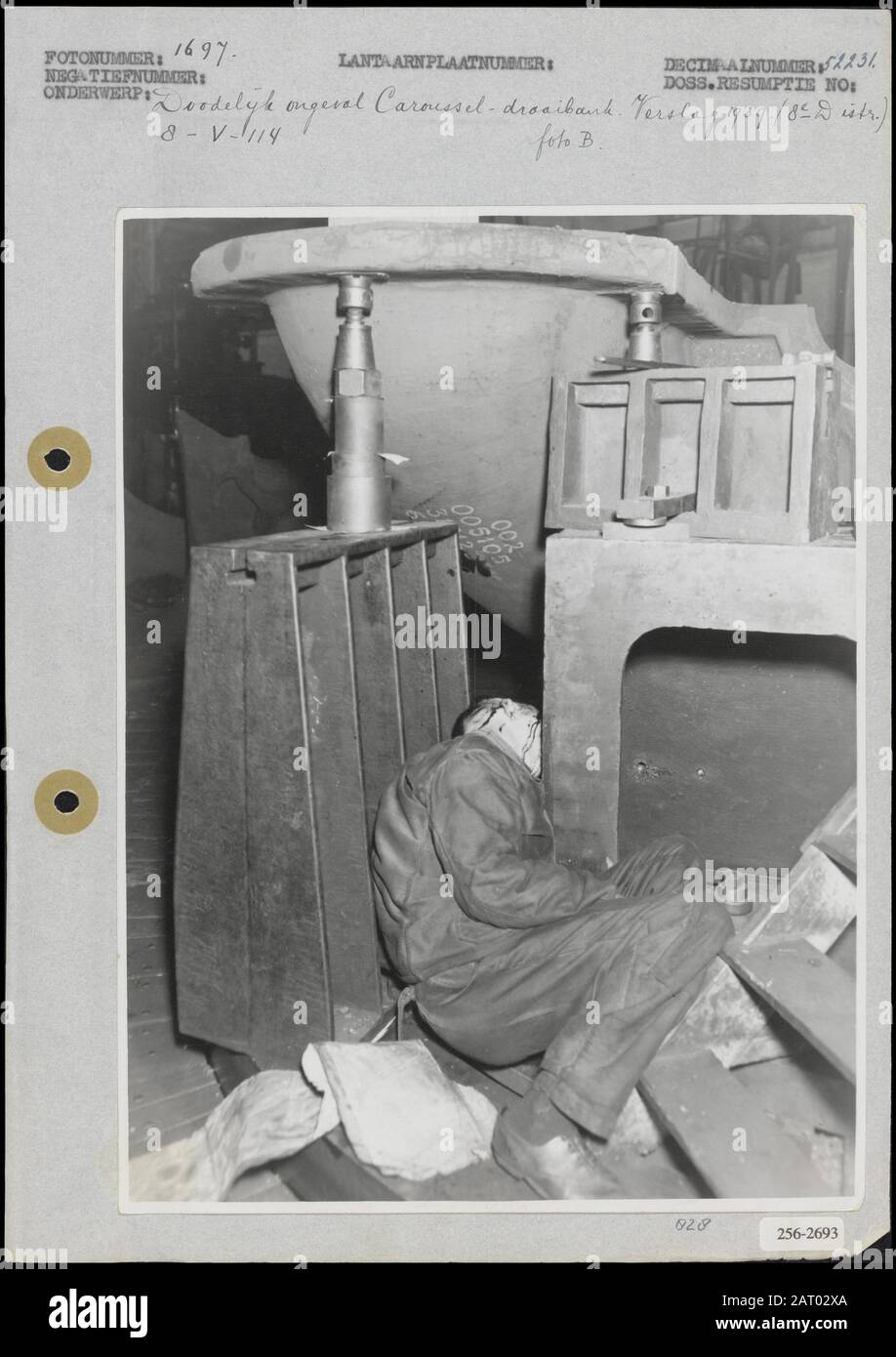

Examining specific case studies of lathe accidents can provide valuable lessons for improving safety practices. For example, a well-documented incident involving a Russian lathe operator highlights the dangers of working without proper supervision and the importance of adhering to safety guidelines.

Lessons Learned from Case Studies

From these case studies, we can derive several important lessons:

- The critical role of supervision in preventing accidents

- The importance of regular maintenance and inspections

- The necessity of thorough safety training for all operators

By learning from past incidents, we can work towards creating safer working environments.

Importance of Machinery Maintenance

Regular maintenance of lathe machines is essential for ensuring their safe and efficient operation. Neglecting maintenance can lead to mechanical failures, increasing the risk of accidents. Key maintenance tasks include:

- Inspecting and replacing worn parts

- Lubricating moving components

- Calibrating machine settings

Establishing a routine maintenance schedule can help prevent many common causes of lathe accidents.

Legal and Regulatory Considerations

Companies operating lathe machines must comply with relevant legal and regulatory requirements to ensure workplace safety. These regulations often include:

- Occupational safety standards

- Equipment certification and inspection requirements

- Reporting and investigating accidents

Staying informed about these regulations is crucial for maintaining compliance and protecting workers.

Conclusion and Future Perspectives

In conclusion, the "Russian lathe accident video" phenomenon has brought much-needed attention to the dangers associated with lathe operation and the importance of workplace safety. By understanding the causes and consequences of these accidents, we can implement effective strategies to prevent them and create safer working environments.

We encourage readers to take action by:

- Sharing this article with others to raise awareness

- Leaving comments or questions for further discussion

- Exploring additional resources on workplace safety

Together, we can work towards a future where lathe accidents are a thing of the past.

Data and statistics referenced in this article are derived from reputable sources such as the Occupational Safety and Health Administration (OSHA) and industry reports. For further reading, consider exploring these resources to deepen your understanding of lathe safety and best practices.